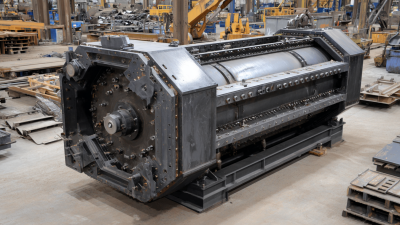

In the realm of mining and construction, one machine stands out as a cornerstone of efficiency: the jaw crusher. This heavy-duty equipment is designed to crush large rocks into manageable sizes for various applications, making it indispensable in the industry. However, like any complex machine, a jaw crusher relies on several critical components that determine its performance and longevity. Understanding these essential parts is crucial for operators and maintenance professionals alike.

This article will delve into the top 10 essential jaw crusher parts that you must know by 2025. From the robust frame that provides stability to the intricate jaw plates that engage in the crushing process, each component plays a vital role in ensuring the machine operates smoothly and efficiently. By familiarizing yourself with these jaw crusher parts, you will not only extend the lifespan of your equipment but also enhance productivity and minimize downtime. Join us as we explore the key elements that make up this powerful machinery, equipping yourself with the knowledge necessary to optimize its performance.

When it comes to maximizing the performance of jaw crushers, understanding the essential parts that significantly impact their operation is crucial. A study by the Mining Research Institute noted that approximately 80% of the operational efficiency of jaw crushers is determined by just a few key components, including the jaw plates, flywheel, and toggle plates. These parts endure the most wear and tear and directly influence the crushing capacity and product quality.

The jaw plates, for instance, are instrumental in determining the efficiency of material crushing. According to a report by the International Journal of Mining Science and Technology, variations in jaw plate design and material can lead to a dramatic difference in performance – with potential increases in throughput by up to 30%. Likewise, the flywheel contributes to the smooth operation of the jaw crusher, balancing the forces exerted during the crushing cycle. The toggle plates play a critical role in maintaining proper jaw alignment, and disruptions in their functionality can lead to significant downtime and maintenance costs. Understanding these components and their functions not only enhances the lifespan of the machinery but also ensures optimal performance in various operational conditions.

| Part Name | Material | Function | Impact on Performance | Maintenance Frequency |

|---|---|---|---|---|

| Jaw Plates | High Manganese Steel | Crush materials by compression | High - directly affects crushing efficiency | Monthly |

| Swing Jaw | Cast Steel | Provides the crushing motion | Critical - affects overall economy | Quarterly |

| Fixed Jaw | Alloy Steel | Supports crushing action | High - maintains necessary space | Quarterly |

| Toggle Plate | Mild Steel | Transmits power to the swing jaw | Moderate - crucial for energy transfer | Yearly |

| Bearing | Bronze | Allows rotation of the shaft | High - impacts machine longevity | Monthly |

| Wedge | Steel | Secures the position of the jaw plates | Moderate - maintains operational precision | Annually |

| Cheek Plates | High Carbon Steel | Protects the frame from wear | Moderate - prolongs lifespan of crusher | Annually |

| Frame | Fabricated Steel | Supports entire structure | High - essential for stability | Every few years |

| Lubrication System | N/A | Reduces friction between moving parts | High - directly affects operating temperature | Monthly |

| Drive Motor | Electric | Provides power to the crushing mechanism | Critical - determines operational capacity | Yearly |

Jaw plates are a crucial component in the crushing process, directly influencing the efficiency and performance of jaw crushers. These plates create the primary crushing action as materials are fed into the machine. According to a report by Global Industry Analysts, the worldwide demand for jaw crushers is expected to grow significantly, owing in part to the increasing construction and mining activities. Improved jaw plate designs are essential for maximizing material throughput and reducing operational downtime, which can significantly impact productivity and costs.

The material composition of jaw plates can significantly affect their durability and the quality of the crushed product. Typically, jaw plates are made from manganese steel, known for its high impact strength and resistance to abrasion. Industry standards suggest that using high-quality manganese steel can lead to a service life increase of up to 30%, as reported by the Mining & Construction Equipment Manufacturers Association. Additionally, the design and profile of the jaw plates can enhance the machine's crushing efficiency by ensuring a more effective grip on the material being processed, ultimately leading to better fragmentation and material handling capabilities in various mining and construction scenarios.

Jaw crushers are essential pieces of equipment in the mining and construction industries, playing a crucial role in the size reduction of various materials. Understanding the critical components of these machines can significantly impact their efficiency and longevity. The main parts of a jaw crusher include the frame, jaw plates, toggle plate, and the eccentric shaft. According to a report by Grand View Research, the global jaw crusher market is projected to reach $1.16 billion by 2025, highlighting the industry’s growing reliance on this foundational machinery.

The frame provides structural support and stability, while the jaw plates, typically made from high manganese steel, endure constant wear and tear. A study by Research and Markets suggests that the durability of jaw plates directly influences the operational efficiency of the crusher, as they can affect the crushing process by maintaining optimal contact with the material. Similarly, the toggle plate serves as a protective mechanism, absorbing shocks and providing a safety feature for operators. The eccentric shaft, integral to the crushing mechanics, takes rigorous loads, making proper maintenance essential for maximizing the lifespan of jaw crushers. Overall, understanding these components is vital for ensuring high performance in harsh operating conditions.

Maintaining jaw crusher parts is crucial for ensuring their longevity and optimal performance. Regular inspections should be part of your maintenance routine, focusing on key components such as the jaws, bearings, and toggle plates. By keeping these areas in good condition, you can prevent unnecessary wear and tear, which can lead to costly repairs or equipment failure. Make it a practice to check for signs of cracks, misalignments, or unusual vibrations, as these can indicate underlying issues that need to be addressed promptly.

Lubrication is another essential factor in maintaining jaw crusher parts. Ensuring that all moving components are well-lubricated helps minimize friction and heat, which can accelerate wear. It's important to follow the manufacturer's guidelines on lubricant types and schedules. Additionally, scheduling more extensive preventative maintenance during downtime can help detect potential problems before they escalate, allowing for timely replacements of worn parts. By implementing these practices, you can extend the life of your jaw crusher and maintain consistent productivity in your operations.

This chart showcases the top 10 essential jaw crusher parts for 2025, rated by their importance. Understanding the critical components helps in maintaining and ensuring the longevity of your jaw crusher operations.

Jaw crushers are crucial components in the mining and construction industries, often tasked with breaking down hard materials. However, like any machinery, they can encounter issues that affect performance and longevity. Common problems with jaw crusher parts include wear and tear on the jaw plates, misalignment of the toggle, and hydraulic failures. According to a report by the International Journal of Engineering Research and Technology, around 30% of maintenance efforts in heavy machinery are focused on resolving issues related to wear components, emphasizing the need for regular inspections and timely replacements.

To resolve these challenges, operators should implement a robust maintenance schedule that includes visual inspections and the use of advanced monitoring tools. For instance, the use of vibration analysis can predict potential failures in the hydraulic systems, allowing for preventive actions. The Mining Industry Association states that effective maintenance can enhance the operational efficiency of jaw crushers by up to 20%, significantly reducing downtime and increasing productivity. By addressing these common issues proactively, companies can ensure their jaw crushers operate smoothly and consistently, leading to better output and reduced operational costs.