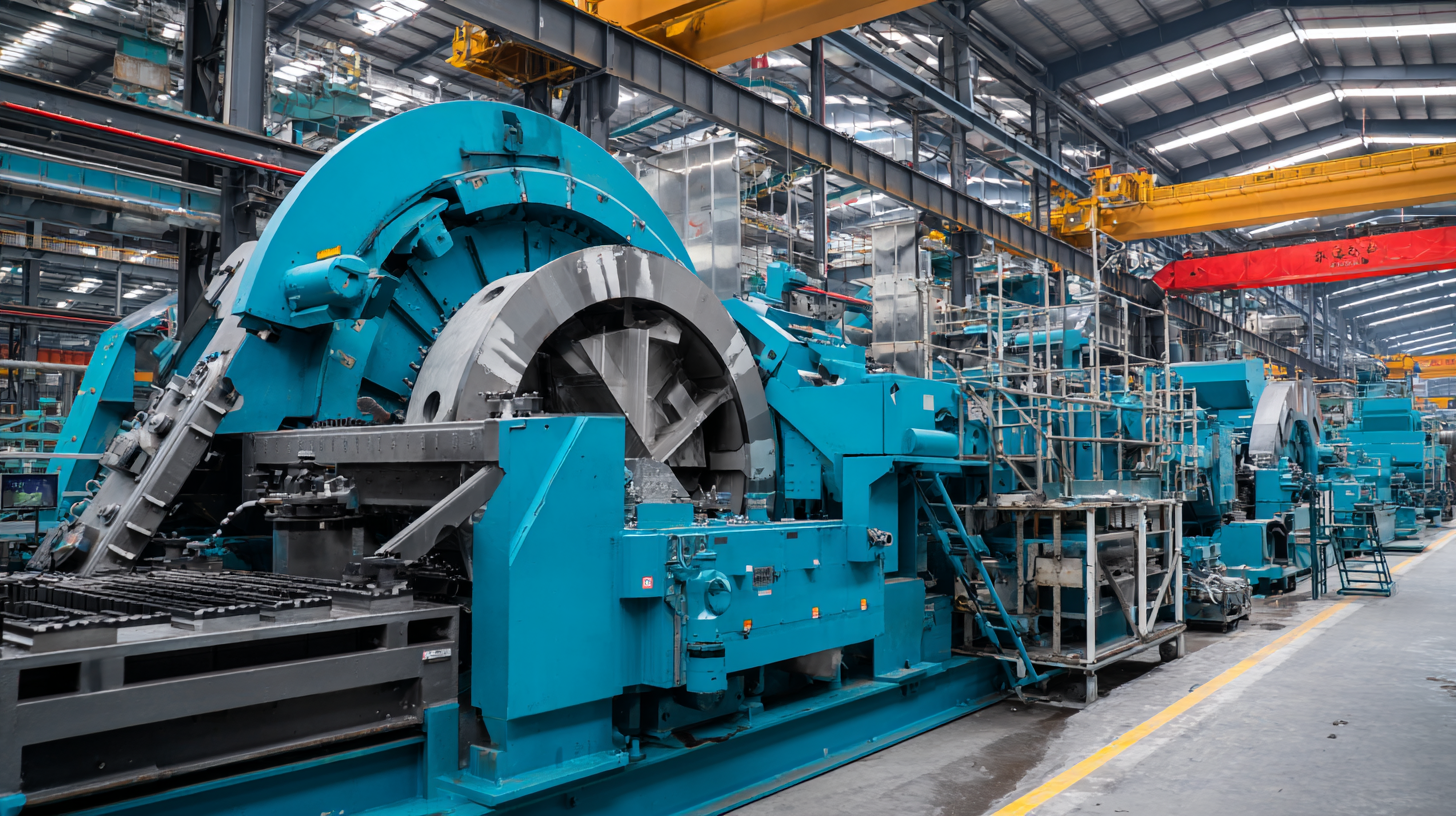

In the rapidly evolving mining industry, the demand for high-quality and durable equipment continues to surge, driving innovations among Jaw Crusher Parts Suppliers. According to a recent report by Mordor Intelligence, the global jaw crusher market is projected to grow at a CAGR of over 6% from 2021 to 2026, highlighting the critical role that these suppliers play in enhancing operational efficiency and productivity. By 2025, advancements in technology and materials are expected to revolutionize the performance of jaw crushers, making it essential for mining companies to align with industry-leading suppliers.

As mining operations become increasingly automated and sophisticated, the focus on sourcing superior jaw crusher parts is paramount to meet stringent quality and longevity standards, ensuring that suppliers who adapt to these changes will be at the forefront of the mining industry's transformation.

When it comes to selecting jaw crusher parts suppliers, understanding the key characteristics that define high-quality providers is crucial for the mining industry. One of the most important attributes is the emphasis on material quality. Reputable suppliers utilize top-grade materials that ensure durability and reliability, which directly impacts the performance and lifespan of the machinery. By sourcing parts made from premium alloys and special coatings, these suppliers help operators minimize downtime and enhance operational efficiency.

In addition to material quality, an excellent jaw crusher parts supplier should offer comprehensive product support and customization options. This includes not just a wide range of parts, but also the ability to customize solutions tailored to specific needs and applications. Knowledgeable suppliers understand the unique operational challenges faced by mining companies and can provide insights on the best configurations and parts that optimize performance.

Strong customer service and technical support are also hallmarks of a top-tier supplier, as they can assist clients in troubleshooting and maintenance, ultimately contributing to the overall success of mining operations.

In the rapidly evolving mining industry, the quality of jaw crusher parts significantly influences equipment performance and operational efficiency. Recent studies suggest that nearly 30% of unplanned downtime is attributed to subpar components, highlighting the critical need for sourcing high-quality suppliers. A 2023 report by the Mining Equipment Manufacturers Association (MEMA) indicates that investing in superior parts can enhance the lifespan of crushers by up to 15%, leading to substantial savings in maintenance and replacement costs.

Tips: Always conduct a thorough background check on potential suppliers. Look for those with strong industry reputations and proven track records of quality. Consider obtaining certifications or reports that validate a supplier's compliance with international standards.

Moreover, the rise of advanced materials and manufacturing techniques has allowed leading suppliers to offer innovative products that improve the longevity and performance of jaw crushers. Companies leveraging technology, such as 3D printing and high-strength alloys, can provide components that withstand higher wear and tear, thus increasing overall productivity. The latest reports suggest that utilizing high-quality components can enhance operational uptime by 25%, therefore maximizing output and profits in an increasingly competitive market.

Tips: Regularly review supplier performance metrics and seek feedback from equipment operators. Establishing long-term partnerships with reliable suppliers can lead to better service and support.

| Supplier Region | Quality Rating | Part Durability (Hours) | Maintenance Frequency (Months) | Cost Efficiency (USD) |

|---|---|---|---|---|

| North America | High | 5000 | 6 | $1200 |

| Europe | Medium | 4500 | 8 | $1000 |

| Asia | Low | 3000 | 12 | $800 |

| South America | Medium | 4000 | 7 | $950 |

In the rapidly evolving mining industry, the role of jaw crusher parts suppliers has become increasingly pivotal, particularly as companies seek to enhance operational efficiency and reliability. Essential certifications and standards are vital for these suppliers to ensure they meet industry demands. According to a report by the World Mining Congress, organizations that adhere to ISO 9001:2015 certification demonstrate a 20% increase in operational efficiency compared to those without it. This standard emphasizes quality management systems that help suppliers maintain consistent product quality, which is crucial for the longevity and performance of jaw crushers.

Moreover, compliance with the ASTM International standards further reinforces a supplier's reliability. Specifically, the ASTM A370 standard for testing mechanical properties can significantly enhance the durability of crusher parts, thereby reducing downtime in mining operations. A study from the International Journal of Mining Science and Technology indicates that equipment failures due to subpar parts can lead to more than a 30% loss in productivity. Thus, by prioritizing essential certifications and adhering to established standards, jaw crusher parts suppliers not only ensure their products meet quality benchmarks but also contribute to the overall efficiency and sustainability of the mining sector.

In the rapidly evolving mining industry, selecting reliable suppliers for jaw crusher parts is paramount for operational efficiency. The utilization of data-driven metrics plays a crucial role in evaluating the reliability of these suppliers. By analyzing performance indicators such as delivery times, product quality, and customer satisfaction ratings, mining companies can make informed decisions that minimize downtime and enhance productivity. Metrics like these not only provide insights into current supplier capabilities but also help predict future performance.

Moreover, the integration of advanced analytics tools allows mining operations to assess supplier performance in real time. This proactive approach enables businesses to quickly identify potential risks and address issues before they escalate. For instance, tracking feedback and warranty claims can reveal patterns that indicate a supplier's reliability. Emphasizing data-driven evaluations fosters a more transparent relationship between mining companies and suppliers, ensuring that partners are held accountable for their commitments while driving continuous improvement in the quality of parts supplied to the industry.

When assessing the cost-effectiveness of jaw crusher parts suppliers, it's essential to consider several key factors that can significantly impact the overall value. According to a recent report by the Mining Equipment Buyers Guide, approximately 70% of mining companies identify maintenance costs as a vital aspect of their operational budgets. Thus, selecting suppliers that offer durable and reliable parts is paramount. High-quality jaw crusher parts not only reduce the frequency of replacements but also enhance the equipment's efficiency, leading to long-term savings.

Another critical factor is the supplier's reputation and service offerings. A study by the International Journal of Mining Science found that suppliers with robust after-sales support and comprehensive warranties are favored by over 60% of mining businesses. This support can include prompt delivery of parts, expert installation services, and availability of spare parts, which collectively minimize downtime. Additionally, analyzing the total cost of ownership by comparing initial purchase costs with expected lifespan and performance metrics can help gauge the supplier's overall effectiveness in the competitive landscape of the mining industry.

This chart illustrates the average cost-effectiveness of different jaw crusher parts suppliers based on their performance and pricing metrics. This data is crucial for assessing suppliers in the mining industry and ensuring optimal investment.